Cnc Bridge Saw Cutting - Precision & High-performance

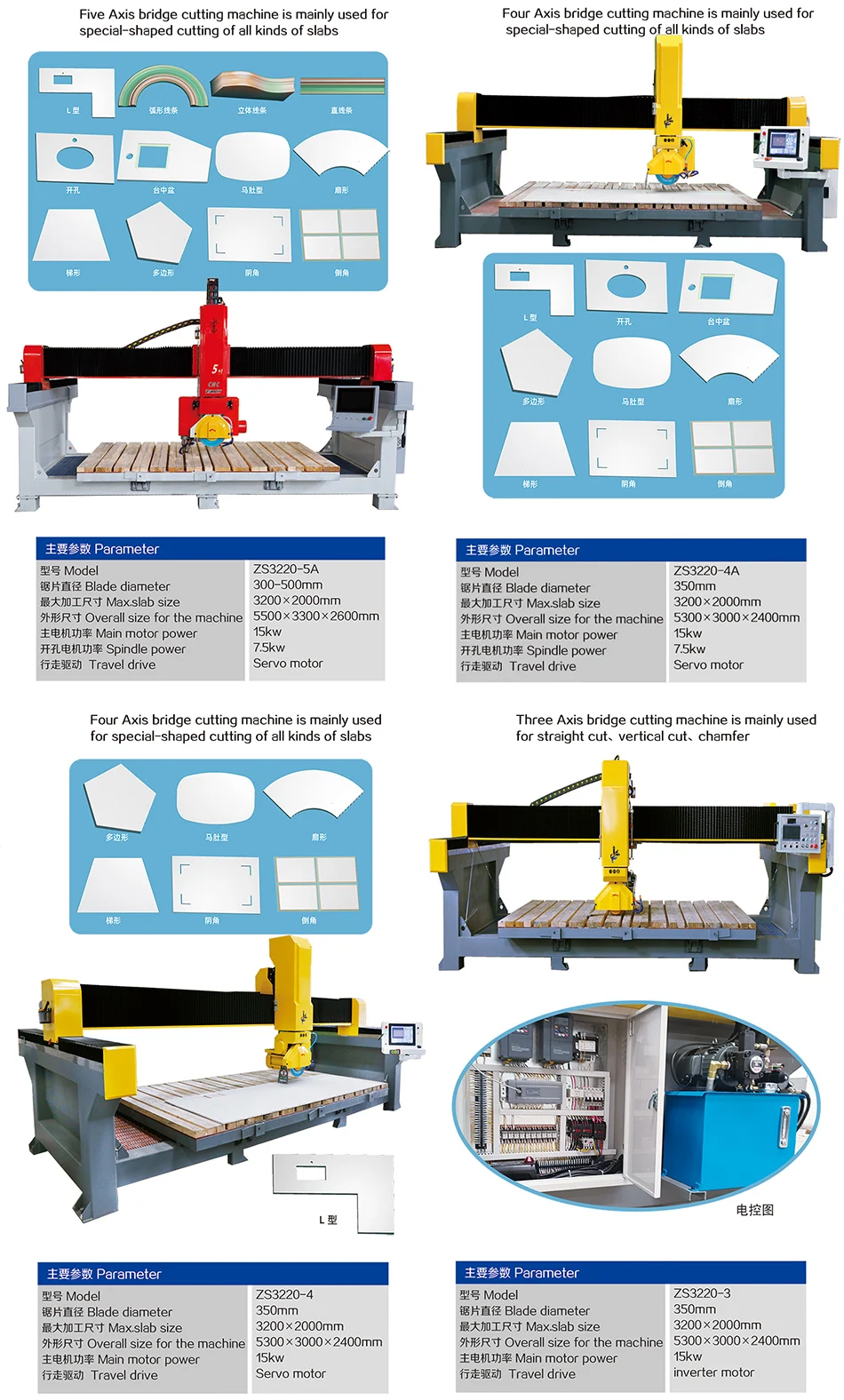

Dechen 5 axis stone cutting machine is pattern operation and advanced control system and synchronous CNC control system, the machine can be easily operated easily without knowing complicated CNC knowledge. This machine can be used to realize some advanced functions like : cutting line, chamfering, drilling, profiling, 3D profiling, and edge profiling, which can be used to small processing factory and countertop shops.

Brief Description

Professionalism: Dechen Machinery specializes in plate cutting equipment, product categories are, five-axis cutting machine, four-axis cutting machine, 4+1-axis cutting machine, three-axis cutting machine, and its supporting products: rock slab chamfering machine, stair tread edging machine, machining center, cutting and grinding machine and other deep processing equipment.

|

Recommended reason: 1. For customers who cut plates in batches, they can choose 5+3 cutting machine, intelligent photography + suction cup moving can improve the utilization rate of plates, complete cutting more efficiently, and save labor. 2. For customers who do copy or special-shaped processing, you can choose a 5-axis cutting machine, which can be completed by cutting all kinds of curved lines and arc fans. 3. For customers who have various processes on a plate, after setting the program, the five-axis can be better and more convenient to complete the processing, simple and time-saving. |

|

|

Blade diameter |

300-500mm |

|

Max. cutting size |

3200*2000*130mm |

|

Main motor power(PMSM) |

18.5kw |

|

Open-hole motors |

7.5kw |

|

A-axis travel |

0-90°(Automatic) |

|

Z-AXIS travel |

±365° |

|

Fast travel speed |

20(m/min) |

|

motor speed |

0-8000(rpm) |

|

Overall dimensions |

5500*3300*2600mm |

|

Voltage/Hz |

380V/50HZ |

In the ever - evolving landscape of stone fabrication, cnc bridge saw cutting, marble cnc machine, and the capabilities of 5 axis quartz granite marble stone cnc milling cut have emerged as game - changers, redefining precision, efficiency, and creativity in the industry. These cutting - edge technologies empower stone processors to take on complex projects and deliver high - quality results that meet the demands of modern architecture and design.

Cnc bridge saw cutting stands at the forefront of stone cutting technology, offering unparalleled precision and productivity. These machines utilize computer - numerical control to execute accurate cuts on a variety of stone materials, from large marble slabs for flooring to granite blocks for countertops. The bridge - type structure provides stability during the cutting process, while the CNC system allows operators to program intricate cutting paths with ease. For large - scale construction projects, such as the installation of stone facades on skyscrapers, CNC bridge saws can quickly and accurately cut stones to the exact specifications, reducing production time and minimizing material waste. Their ability to handle heavy - duty cutting tasks makes them a staple in stone processing facilities worldwide.

Feature

1. Compact size without needing the ground base.

2. With advanced CNC control system and all pattern operation, the machine can be operated without professional operators.

3. With powerful functions, the machine can work almost all the jobs of a small factory.

4. With less electricity and more efficiency, the cost is decreased much.

5. High quality accessories and electric parts are used to secure long service life and low cost.

Application

The machine endowed with high steadiness,effective and simple in operating characters,Hence,It is suitable to process high value,large size granite and marble slab.

Marble cnc machine has revolutionized the way marble is crafted, enabling the creation of intricate designs and delicate details. Marble, with its unique veining and elegance, requires a high level of precision during processing. CNC technology ensures that every cut, engraving, or shaping operation on marble is executed flawlessly. Whether it’s producing ornate marble sculptures, crafting custom - designed marble fireplace surrounds, or fabricating high - end marble bathroom vanities, these machines bring designers’ visions to life. The automated control system of a marble CNC machine also reduces the risk of human error, guaranteeing consistent quality in every piece of marble work, which is highly valued by clients in the luxury construction and interior design sectors.

Company Information

Laizhou Dechen Machinery Technology Co., Ltd is a large-scale comprehensive enterprise engaged in stone machinery with R&D, manufacture, sales and service.

The Company is located in Xiaqiu Town Laizhou City, the largest stone material base in Northern China.

Dechen stone machinery is the brand product in China’s stone industry. we export our products to the southeast Asia, Africa, South America and other dozens of countries, getting highly praise from our customers overseas it relys on the high quality, exquisite technology and perfect service system.

The 5 axis quartz granite marble stone cnc milling cut represents the pinnacle of stone machining capabilities. With five axes of movement, these machines can perform complex 3D milling operations on quartz, granite, and marble, allowing for the production of highly detailed and sophisticated stone products. From creating elaborate relief carvings on granite monuments to shaping intricate patterns on quartz kitchen islands, the 5 - axis CNC milling technology offers limitless design possibilities. The multi - axis functionality enables simultaneous cutting from multiple angles, reducing the need for repositioning the stone and enhancing overall efficiency. In addition, the high - speed spindles and advanced cutting tools of these machines ensure a smooth finish on even the hardest stone materials, making them ideal for high - end stone projects that demand both precision and aesthetic appeal.

Exhibition

Our company has participated in the Canton fair several times, the sino-kazakhstan trade conference and other large international conferences, and has received wide recognition and support from customers.

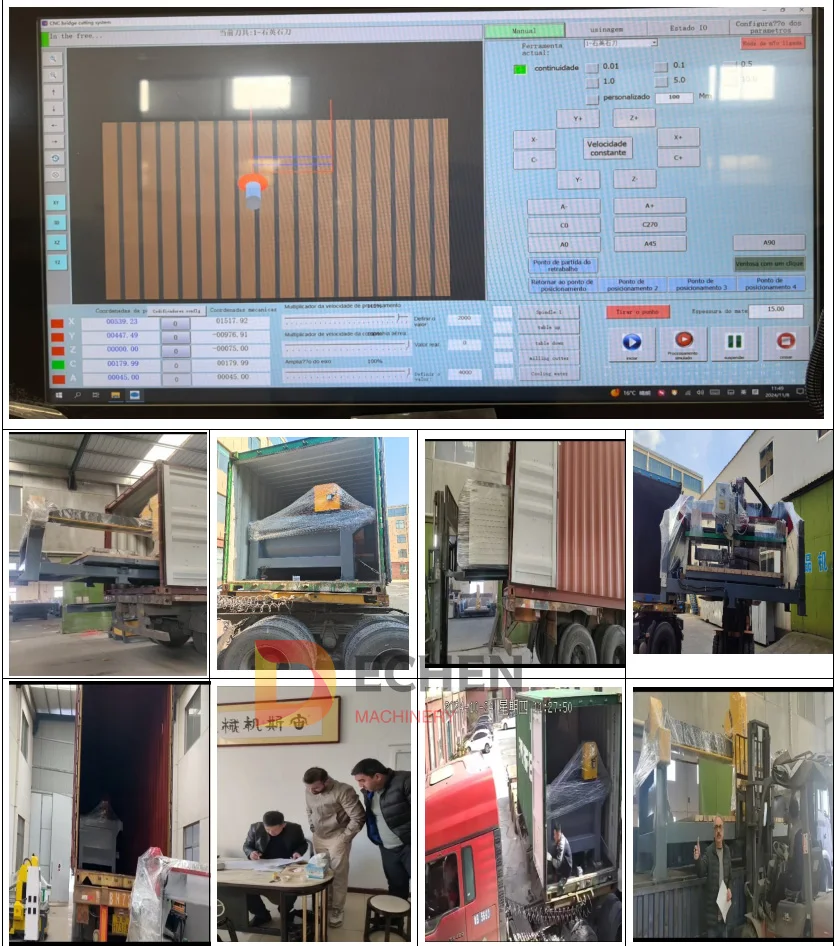

Packaging & Shipping

1.After the package is qualified and complete, we will use the international standard export and the customer's requirements to ensure the transport of the products.

2.We can offer different delivery terms for different quantities. (sea,express, etc.) and according to customer requirements on time delivery.

Our Services

1) Professional OEM service: motor power,color and sizes can be customized according to customer's special requirement.

2) Strong quality control: We use high quality materials and strict quality control system. Our QC department consistently operates throughout the whole product process according to related standards.

3) Competitive price and delivery in time: We are exporter based on manufacturer. so that we can control the cost and the delivery time.

4) More professional export work: Well-trained & experienced staff are ready to provide you good service from consultation to after sales service.

5)MOQ: One set Order accept.

6) Design: More than 20 different types of products can be supplied to you.

7) Inspection: You can inspect the shipment by third party before shipping out.

8) Refund Money: Refund money within 7 days in case of bad quality.

FAQ:

1)Q: About MOQ

--- As customers’ options.

2)Q: About customization

--- ODM/OEM business partner will be warmly welcome.

3)Q: About price

--- Price is based on QTY, payment terms, time of delivery.

4)Q: How to request machine?

--- you just tell us.

5)Q: When you ship my order ?

--- Normally 15-20days after receiving final payment, but it can be negotiated if customers need urgently.

6)Q: How can you guarantee the production quality ?

--- We have strictly quality control system in our production process. All products must be double checked during every manufacturing process. Requirement of customers and quality of products will be full guaranteed.

7)Q: After I buy the machine, how I can install and operate it ?

--- We strongly suggest customer to ask our engineer to come to help you to install the machines, teach your operator how to operate and maintain the machines.

8)Q: Other problems ?

--- If you have any other questions, we have professional senior account managers who can provide services for you at any time. Click the business card below to communicate and solve your problems in time.

Send your inquiry Details in the Below for more information click "Send" Now!

Plsease input value

Plsease input value